HIGH PERFORMANCE CUTTING PLOTTER

600G Down Force | 58.5 Inches Per Second | 50ft. Accurate Tracking

Known around the world for its high precision cutting, and build quality, the FC8600 is the ultimate finishing solution for the signage, apparel, and automotive markets.

Included Graphtec Pro Studio and Cutting Master 4 software provide all of the tools needed to create stunning print & cut signage, decals, apparel and more. Utilizing the strength of the Advanced Registration Mark Sensing system (ARMS), and its 600g of down force, even the most challenging medias such as high intensity reflective are cleanly cut.

Available In 5 Cutting Widths

FC8600-60 (24") | FC8600-75 (30”) | FC8600-100 (42”) | FC8600-130 (54”) | FC8600-160 (64”)

Prismatic Grade Reflective Sheeting

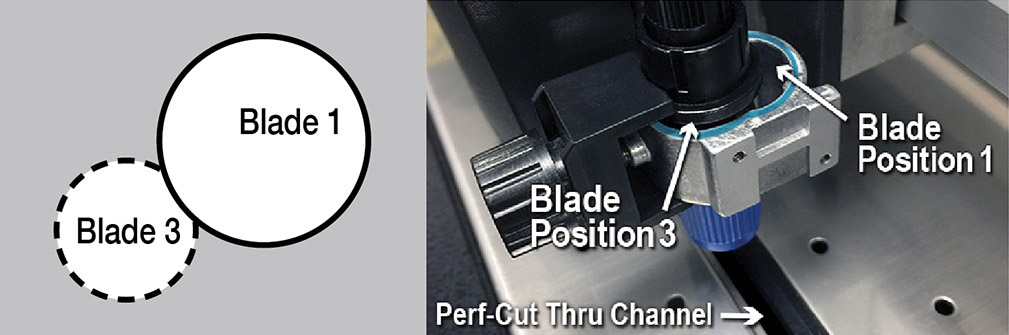

PERF CUT Enabled High Performance Cutters Finish The Job

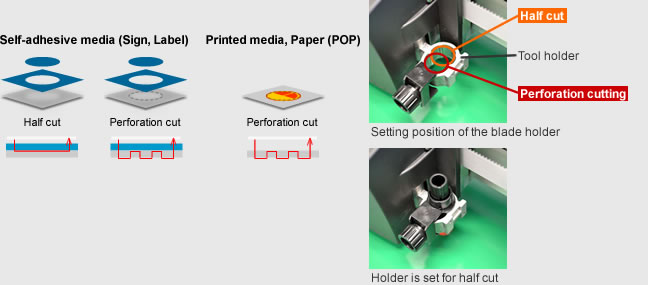

With its included perf cut enabled custom tool settings - you have the ability to perforate cut all the way through your pre printed vinyl media creating pop-out, full-color stickers and decals without damaging your blade or cutting plotter machine.

Blade position 1 is for contour kiss cutting of vinyl media. Blade position 3 allows the blade to cut all the way through the media into the channel without damaging the cutting strip and blade.

Perforation cutting is performed by controlling the cutting force instead of blade up/down movements, increasing throughput. This is perfect for cutting separation lines for tearing out labels, fold lines for POP signs, and others.

Auto Mark Detection

The first registration mark is automatically detected within a wide search area; this eliminates the need to manually move the sensor near the registration mark position. Subsequent marks are automatically located which improves the operation of the registration mark searching.

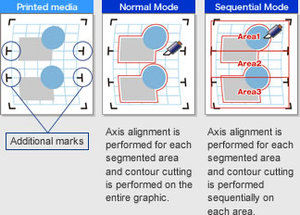

Segment Area Compensation

A 4-point axis alignment is performed for each segmented area.

In Normal Mode, this is performed by reading the marks in the middle of the feeding direction for the entire graphic and then cutting the entire graphic, providing high-precision alignment for long length Print & Cut applications.

In the new Sequential Mode, contour cutting is performed sequentially in each segmented area. Media movement is limited to the smaller area being cut, improving accuracy and tracking for heavier media or media that has been laminated.

* Normal mode is available when Graphtec Studio, Graphtec Pro Studio, Cutting Master 2/3/4, or Plotter Controller software is used.

* Sequential mode is available when Graphtec Studio (ver. 2.1.200 or later) or Cutting Master 3 (ver. 2.1.211 or later) is used.

* This function is available in firmware version 2.10 or later.

Multiple-Mark Compensation

When the design is printed with the matrix copy function, the action of reading the marks and contour cutting is repeated for each copy. It significantly improve productivity for Print & Cut.

* This function is available when the Graphtec Studio, Graphtec Pro Studio, Cutting Master 2/3/4 software is used.

ISM (Intelligent Scan Mode)

The ISM incorporates a new scanning algorithm that not only expands the cutting range of compatible media, but also reduces scan times and increases mark scanning success. Registration marks are also detectable on colored media and textured media, such as glossy laminated materials that were difficult using the conventional method.

* Media must be within the specification in range. Marks may not be detected due to poor print quality or media surface.

* This function is available in firmware version 2.10 or later.

| Model | FC8600-60 | FC8600-75 | FC8600-100 | FC8600-130 | FC8600-160 |

|---|---|---|---|---|---|

| CPU | 32-bit CPU | ||||

| Configuration | Grit rolling type | ||||

| Drive method | Digital servo drive | ||||

| Max. cutting area (W x L) (*1) | 2 ft x 164 ft 610 mm x 50 m |

2 ft 6 in x 164 ft 762 mm x 50 m |

3 ft 6 in x 164 ft 1067 mm x 50 m |

4 ft 6 in x 164 ft 1372 mm x 50 m |

5 ft 4 in x 164 ft 1626 mm x 50 m |

| Cutting area of guaranteed accuracy (*2) | 23.23 in x 50 ft | 29.21 in x 50 ft | 41 in x 32 ft, 35.2 in x 50 ft |

53 in x 32 ft, 35.2 in x 50 ft |

63 in x 32 ft, 35.2 in x 50 ft |

| Mountable media width | Min. 1.97 in |

Min. 1.97 in |

Min. 1.97 in |

Min. 1.97 in |

Min. 1.97 in |

| Max. cross cut width | 2 ft 4.9 in (734 mm) | 2 ft 10 in (886 mm) | 3 ft 10.88 in (1191 mm) | 4 ft 10.9 in (1496 mm) | 5 ft 8.9 in (1750 mm) |

| Number of push rollers | 2 rollers | 2 rollers | 3 rollers | 3 rollers | 4 rollers |

| Max. cutting speed | 4 ft 10.46 in/s (1485 mm/s) at 45° direction | ||||

| Axial acceleration | Max. 39.2 m/s2 (4 G) in 8 steps | ||||

| Cutting force | Max. 5.88 N (600 gf) in 48 steps | ||||

| Mechanical resolution | 0.005 mm | ||||

| Programmable resolution | GP-GL: 0.1 / 0.05 / 0.025 / 0.01 mm, HP-GL™: 0.025 mm | ||||

| Distance accuracy (*2) | Max. 0.1 mm or 0.1 % of plotted length | ||||

| Repeatability (*2) | Max. 0.1 mm in plot up to 2 m (excluding the expansion and contraction of the media) | ||||

| Minimum character size | Approx. 3 mm alphanumeric (varies depending on character font and media) | ||||

| Mountable number of tools | 1 tool (cutting blade, plotting pen or pouncing tool) in standard; 2 tools (cutting blade and plotting pen) when second penholder (optional) is installed |

||||

| Blade types | Supersteel (0.9 mm or 1.5 mm diameter) | ||||

| Pen types | Water-based fiber-tip pen, Oil-based ballpoint pen | ||||

| Pouncing tool type | Steel pin 1.2 mm diameter, required optional pouncing tool (PPA 33-TP12) | ||||

| Media types (*3) | Self-adhesive marking film (vinyl, fluorescent, reflective, high-intensity reflective film) up to 0.25 mm thick, Sandblast resist rubber up to 1 mm thick |

||||

| Compatible paper for pouncing | Regular paper from 0.06 to 0.13 mm thick | ||||

| Light pointer | Built into the tool carriage | ||||

| Cross-cutter | Built into the tool carriage | ||||

| Perforation cutting | Supported (performed by force control) | ||||

| Registration mark sensing system | Scans the mark by optical sensor (ARMS5.0), Segment area and Multiple-mark compensation, 4-points axis alignment, Auto mark detect | ||||

| Standard interface | USB2.0 (High speed), RS-232C, and Ethernet (10BASE-T/100BASE-TX) | ||||

| Buffer memory | 2 MB | ||||

| Command sets | GP-GL / HP-GL™ emulation (Set by menu or command, and selects from GP-GL, HP-GL™, or Auto select) | ||||

| Condition settings | Dual configuration (save two (2) user settings with eight (8) separate condition setting for each user) | ||||

| Display | Graphic type LCD (3-inch, backlight) | ||||

| Power source | 100 V to 240 V AC, 50 / 60 Hz | ||||

| Power consumption | Max. 160 VA | ||||

| Operating environment | 10 to 35 °C, 35 to 75 % R.H. (non-condensing) | ||||

| Guaranteed accuracy environment | 16 to 32 °C, 35 to 70 % R.H. (non-condensing) | ||||

| External dimensions (W x D x H) | Approx. 44" x 28" x 48" (1120 x 711 x 1219 mm) |

Approx. 50" x 28" x 48" (1270 x 711 x 1219 mm) |

Approx. 61.8" x 28" x 48" (1570 x 715 x 1219 mm) |

Approx. 73.6" x 28" x 48" (1870 x 711 x 1219 mm) |

Approx. 84" x 28" x 48" (2130 x 711 x 1219 mm) |

| Weight | Approx. 38 kgs / 106 lbs including stand |

Approx. 52 kgs / 115 lbs including stand |

Approx. 60 kgs / 133 lbs including stand |

Approx. 68 kgs / 150 lbs including stand |

Approx. 73 kgs / 161 lbs including stand |

| Included software (*4) | Windows driver, Plotter controller, Graphtec Pro Studio (*5), Cutting Master 4, Graphtec Studio for Mac |

||||

| Compatible OS (*4) | Windows 10 / 8.1 / 8 / 7 Mac OS 10.7 to 10.14 |

||||

| Compatible Standards | UL60950-1, cUL, CE mark (Low voltage and EMC), KC mark (Low voltage and EMC) | ||||

| FCC-A, EN55022-A | |||||

*1. When the 2nd pen holder is installed, the maximum cutting width is changed. (FC8600-60: 601 mm, FC8600-75: 753 mm, FC8600-100: 1053 mm, FC8600-130: 1352 mm, FC8600-160: 1613 mm)

*2. Operated with Graphtec specified media and conditions. In long-length cutting, the basket is used.

*3. When some grades of high-intensity reflective film is used, the using CB15UA/CB15UA-K30 blade and reinforcing the backing sheet of the media are recommended.

*4. For more information about compatibility of the OS or application software, please check the Graphtec website or contact your local representative of Graphtec.

*5. The software can be used by downloading from Graphtec website.

Looking for quality vinyl cutter machine for commercial, intermedia or entry level, Graphtec can help your vinyl cutting process become easier and improve productivity. Graphtec globally manufactures hight quality vinyl cutter machines. With years of experience in plot cutter, Graphtec is industry leader in desktop vinyl cutter, desktop vinyl cutter machine, sticker cutter, sticker cutter machine, sticker cutting machine. Graphtec is trusted by world renowned organizations around the world, our cut plotter precisely cut vinyl sheet and cut vinyl roll. If you are looking for the high quality vinyl roll feed cutters, Graphtec specialists are onsite to provide you guidelines on how to choose roll feed cutter machine or flatbed cutter machine to suit your production needs, we have you covered!

| Item | Q'ty | Description | |

|---|---|---|---|

| Power cord | 1 | The type of cord is different by destination | |

| Cutting blade holder | 1 | PHP33-CB09N-HS | |

| Cutting blade | 1 | CB09UB | |

| Fiber-tip pen holder | 1 | PHP31-FIBER | |

| Water-based fiber-tip pen | 1 | KF700-BK (black ink) | |

| Stand | 1 | Parts kit of stand | |

| Media stocker | 1 | Set of stock rollers and mounting brackets (Installed on the stand) | |

| Basket | 1 | Parts kit for Basket | |

| USB cable | 1 | Cable for USB2.0, 2.9m long | |

| DVD-ROM | 1 | User manual (PDF format), Windows driver, Software (Plotter controller, Graphtec Pro Studio, Cutting Master 4) | |

| Manual | 2 | Quick start and safety guide | |

Options

| Item | Part No. | Description |

|---|---|---|

| Additional Media Stocker | RSK0020 | For FC8600-60 (Stock roller, bracket) |

| RSK0021 | For FC8600-75 (Stock roller, bracket) | |

| RSK0022 | For FC8600-100 (Stock roller, bracket) | |

| RSK0023 | For FC8600-130 (Stock roller, bracket) | |

| RSK0024 | For FC8600-160 (Stock roller, bracket) | |

| 2nd pen holder | ECK0009 | For dual tool configuration (dealer option) |

| Flange | OPH-A21 | Flange for media holding |

| Additional Push Roller | OPH-A22 | One additional push roller |

| AKZ kit for Window Tint | AKZ-KIT | Anti-static string, magnets,and 2 pack of CB09UB-K60 blades |

Supplies

| Item | Part No. | Description | Package |

|---|---|---|---|

| Cutting blade holder | PHP33-CB09N-HS | For CB09U series blade | 1 set/pack |

| PHP33-CB15N-HS | For CB15U series blade | 1 set/pack | |

| PHP35-CB09-HS | For CB09U series blade | 1 set/pack | |

| PHP35-CB15-HS | For CB15U series blade | 1 set/pack | |

| Cutting blade | CB09UB-5 | 0.9mm dia. 45º angle, Supersteel | 5 blades/pack |

| CB09UB-K60-5 | 0.9mm dia. 30º angle, for thin film (Japan 60º) | 5 blades/pack | |

| CB15U-5 | 1.5mm dia. 45º angle, supersteel | 5 blades/pack | |

| CB15U-K30-5 | 1.5mm dia. 30º angle, for sandblast rubber (Japan 60º) | 5 blades/pack | |

| CB15UA-5 | 1.5mm dia. 45º angle, for high intensity reflective film | 5 blades/pack | |

| CB15UA-K30-5 | 1.5mm dia. 60º angle, for high intensity reflective film (Japan 30º) | 5 blades/pack | |

| Cross-cutter blade | CT01H | Standard type | 1 blade/pack |

| CT02U | High durability type | 1 blade/pack | |

| Water-based fiber-tip pen, and pen holder | KF700-BK | Pen (black) | 10 pens/pack |

| KF700-RD | Pen (red) | 10 pens/pack | |

| KF700-BL | Pen (blue) | 10 pens/pack | |

| PHP31-FIBER | Pen holder for KF700 series pen | 1 set/pack | |

| Oil-based ballpoint pen, and pen holder | KB700-BK | Pen (black) | 10 pens/pack |

| PHP34-BALL | Pen holder for KB700 pen | 1 set/pack | |

| Pouncing tool | PPA33-TP12 | Steel pin 1.2 mm dia. | 1 set/pack |

Looking for high quality vinyl cutter machine for commercial, vinyl cutter for intermedia level or vinyl cutter for entry level, Graphtec can help your vinyl cutting process become easier and improve productivity. Graphtec globally manufactures high quality vinyl cutter machines. With years of experience in plot cutter, Graphtec is industry leader in desktop vinyl cutter, desktop vinyl cutter machine, sticker cutter, sticker cutter machine, sticker cutting machine. Graphtec is trusted by world renowned organizations around the world, our cut plotter precisely cut vinyl sheet and cut vinyl roll. If you are looking for the high quality vinyl roll feed cutters or flat bed cutters; desktop vinyl cutter, small sized vinyl cutter, medium sized vinyl cutter, large format vinyl cutter, Graphtec specialists are onsite to provide you guidelines on how to choose roll feed cutter machine or flatbed cutter machine to suit your production needs, we have you covered!