FC4500 Series

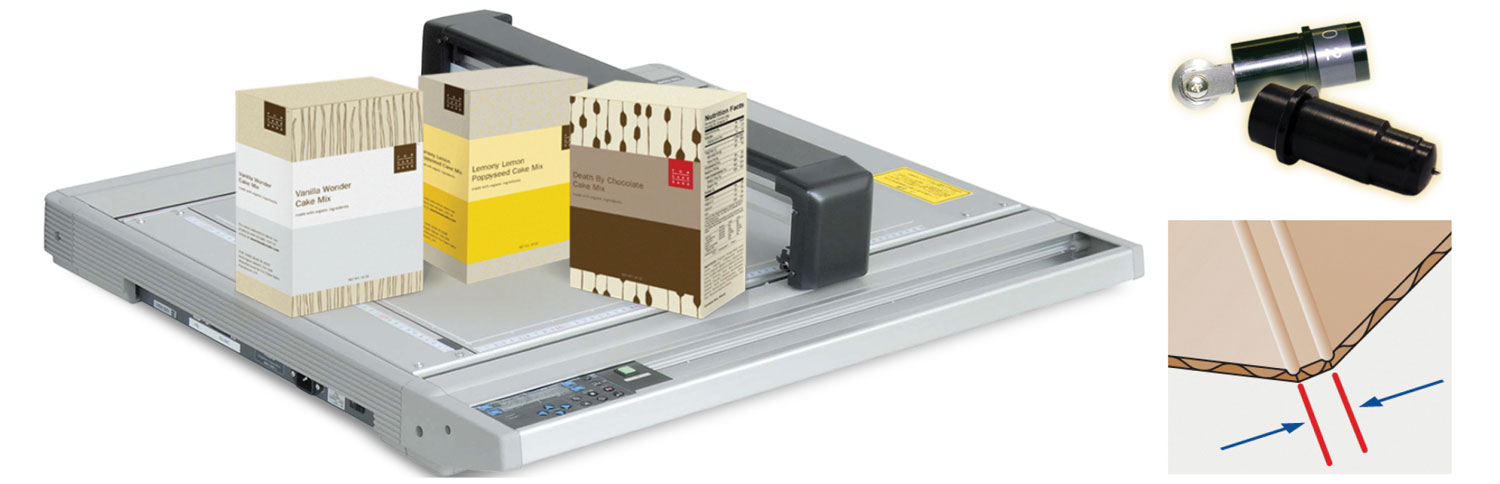

Professional flatbed cutting plotters (in a more compact size) capable of processing various materials with accuracy compliant to most industry requirements for pattern making. FC4500 Series are the ideal cutting plotter for high-precision and medium-heavy material crafting jobs and is suitable for cutting intricate designs on vinyl, photo-masking films, foam material, cardboard, oil board, and sandblast resist rubber. Suitable for PET (polyethylene terephthalate), Polyamide, Stiff paper, Cardboard, Microflute board or Industrial materials with precise adjustable cut pressure up to 600 gf. Flatbed FC4500 Series is the most economical solution for cutting thick, hard materials that cannot be fed through a roll-feed/friction-feed cutting plotter.

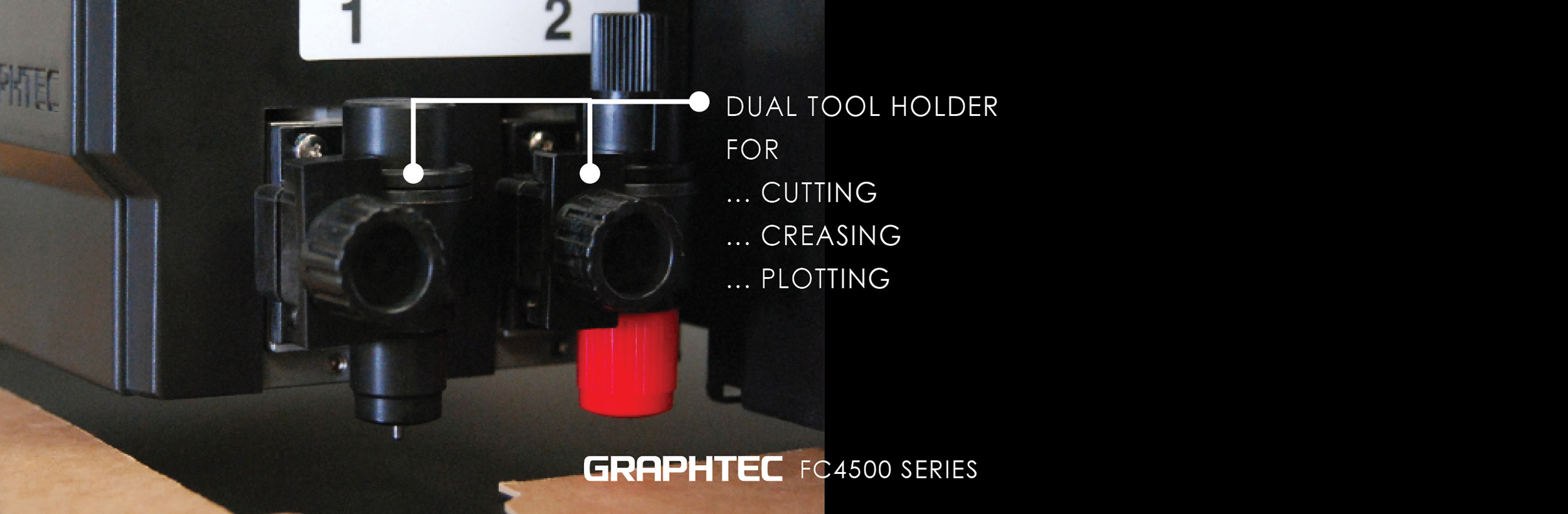

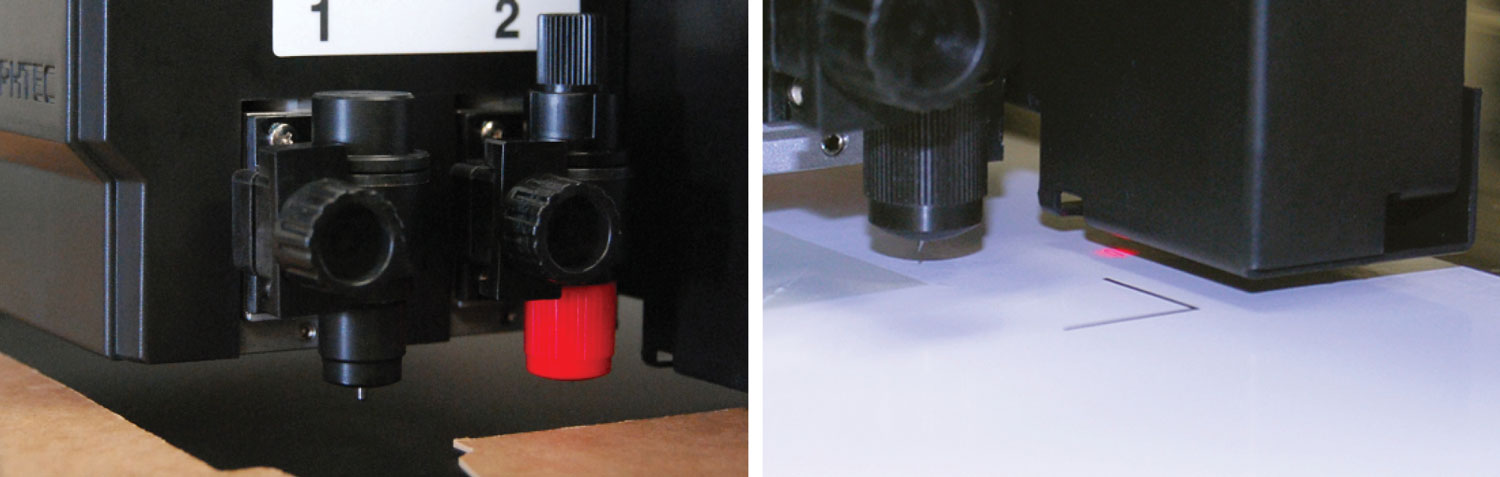

Graphtec FC4500 Series come standard with a dual head configuration allowing pens, cutting tools, and creasing tools to be loaded simultaneously. A new reverse creasing function allows alignment and creasing on the reverse side of the printed card stock to prevent traces of the creasing operation from appearing on the printed surface. A simple function to create fold lines for clean folding on micro-flute and cardboard has been enabled. Up to three fold lines can be selected. If two or three fold lines have been selected, the spacing between the lines can also be specified. Repeated creasing operations can also be specified for each of the lines.

Cutting and creasing can be carried out from reverse-side when using the registration marks. This prevents crease line from appearing on the printed surface. Graphtec FC4500 Series are perfect for designers and prototyping in the offset printing, digital printing, packaging industry, fashion industry, as well as road sign making, stone & glass sandblasting/etching, the electronic film industry, and architectural model building.

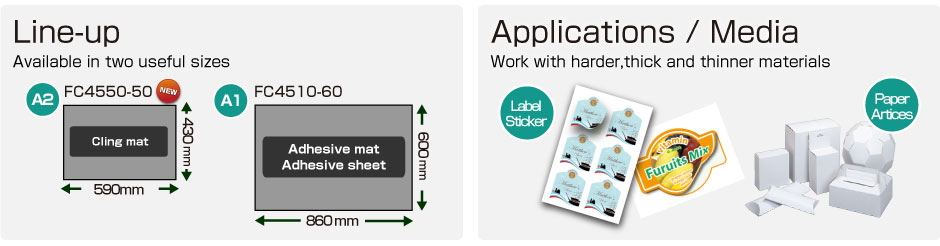

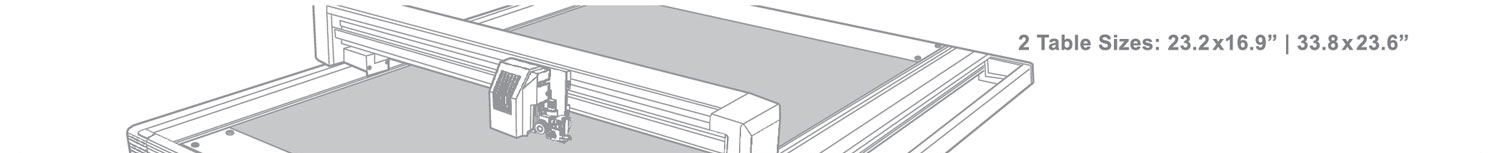

FC4500 Series are intermediate-format, professional flatbed cutting plotters capable of processing a wide variety of materials with accuracy — compliant to most industry requirements for pattern making. The series includes two table top models, the FC4550-50 and the FC4510-60. An optional stand is available for the FC4510-60.

Equipped with the ARMS (Automatic Registration Mark Sensing system). Enables higher productivity of POP, stickers and prototype cartons. Precise control of contour cut, half cut, perforated cut, and plotting. Ideal for creating samples or small production runs.

Interface—USB 2.0 / Serial RS-232C | Reverse side cutting & creasingServo Motor | Cut, contour cut & crease up to 1 mm pre-printed card stocks/boards

FC4500 Series comes with 2 Year Standard Warranty.

2 Models:

FC4550-50 (23.2″ x 16.9″) - electrostatic and adhesive sheet

FC4510-60 (33.8″ x 23.6″) - adhesive mat and adhesive sheet

Includes: D-Cut Master software (Windows), Graphtec Pro Studio software & Cutting Master 4 plug-in for Illustrator & CorelDraw (Macintosh & Windows compatible).

* 1 For Macintosh, It needs to be used the Cutting Master 4 that is plug-in software for Illustrator.

MAXIMUM 600 GRAM OF FORCE

STRONGER FORCE TO HOLD MEDIA FROM 30 MM TO 20 MM

LOW TACK CLING MAT (CM-0004)

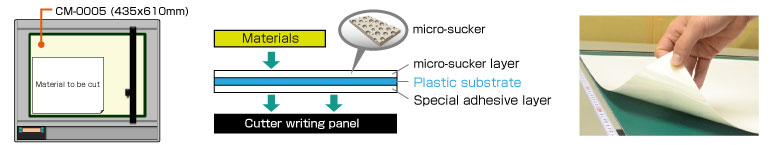

MICRO SUCTION CLING MAT (CM-0005)

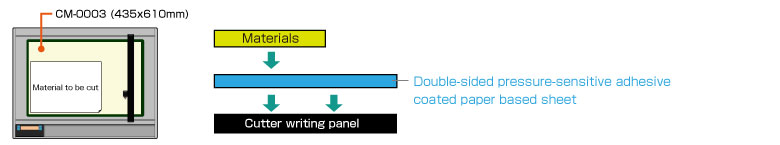

ADHESIVE MAT (CM-0002), ADHESIVE SHEET (CM-0003)

DUAL TOOL HOLDER FOR CUTTING AND CREASING (FC4510-60 model)

Both models are equipped with two Tool Holders for cutting, creasing and plotting. For graphic design and packaging mock ups, the FC4510-60 has the dual Tool Holder which can hold a cutting blade and creasing tool — to produce creases/folds and cuts on the same run.

With their capability to hold both a cutting blade and a plotting pen simultaneously, the FC4500 Series allows garment and shoe pattern designers to mark and cut the material without manually replacing the marking and cutting tools.

Maximum cutting speed is 750mm/s

Table top type cutting plotter with excellent cost performance

Flatbed cutting plotter is used for not only sign making but also for a wide range of industrial applicaitons and processes. Max.750mm/s cutting speed is useful for getting high productivity.

FC4500 Series are professional flatbed cutting plotters capable of processing a wide variety of materials with accuracy. Compact size that can be set on a table with precise control of contour cut, half cut, perforated cut, and plotting.this FC4500 Series is the most economical solution for cutting thick, hard materials that cannot be fed through a grit rolling type cutting plotter.

Media hold-down method

It is very important to select exact media hold-down method in order to perform a precise cut. FC4550 Series provide the following method to fit a variety of media:

NEW! Low tack cling mat (CM-0004)

The media is held by the dot shaped adhesive material on the low tack cling mat. Low tack cling mat size: 17.126 in x 24.0157 in, thickness 0.4 mm. It is suitable for plastic film based media.

NEW! Micro suction cling mat (CM-0005)

The media to be cut is held to the cutter by the micro-sucker on the cling mat. Micro suction cling mat size: 17.126 in x 24.0157 in, thickness 0.8 mm. It is suitable for paper based media.

Adhesive mat (CM-0002)

The media to be cut is held to the cutter by the sticky soft plastic mat. Adhesive mat (soft mat for making the creasing) size: 17.126 in x 24.0157 in, thickness 1 mm. It is suitable for cardboard.

Suitable materials (media)

- Coated cardboard for paper articles - Micro Flute board for package

Adhesive sheet (CM-0003)*

The media to be cut is held to the cutter by the pressure-sensitive adhesive on the adhesive sheet. Adhesive sheet (double-sided adhesive coated sheet) size: 21.45 in x 65.6 ft. It is suitable for harder media that needs higher cutting forces.

* Supplying in roll. It is used by cutting to the required size.

SUITABLE MATERIALS (MEDIA)

- Marking film, PVC (Vinyl) - Labels/stickers, Film/paper - High-intensity reflective film - Cardboard (Paper articles, POP, POD)

- Paper with lamination - Micro flute board (F/G grades)

| Material (Media) | CM-0004 (Low tack type) |

CM-0005 (Micro suction type) |

CM-0002 (Adhesive mat) |

CM-0003-R1A (Adhesive sheet) |

|---|---|---|---|---|

| PVC (Vinyl) film for Marking, Sign | No good (*1) | Excellent | N/A | Good (*2) |

| Film / paper for label or sticker | No good (*1) | Excellent | N/A | Good (*2) |

| High-intensity reflective film for SIgn | No good (*1) | Excellent | N/A | Good (*2) |

| Cardboard for POP | No good (*1) | Excellent | N/A | Good (*2) |

| Coated cardboard for POP | No good (*1) | Excellent | N/A | Good (*2) |

| Paper with lamination for POS | No good (*1) | No good | N/A | Excellent |

| Coated cardboard for paper articles | No good (*1) | Excellent | Excellent | Good (*2) |

| Micro Flute board for package | No good (*1) | Excellent | Excellent | Good (*2) |

| Highly-functional film with backing sheet for Industry | Excellent | Very good | N/A | Good (*2) |

| (CM-0004 is suitable) | ||||

| Highly-functional film for Industry | Excellent | Very good | N/A | Good (*2) |

| (CM-0004 is suitable) | ||||

| Stiff paper / card for Garment, Shoes | No good (*1) | Excellent | N/A | Good (*2) |

| High-quality paper for marking | No good (*1) | Excellent | N/A | N/A |

Assessment varies by the material. There is different characteristic materials in the same category. Please evaluate with the material that is actually used.

*1. Adhesive force will be weakened by the paper dregs in not many cuts. The mat needs to be frequently replaced. Do not recommend for this material.

*2. It may occur curling of the material by strong stickiness when it is peeled off from mat.

| Model name | FC4550-50 | FC4510-60 |

|---|---|---|

| Configuration | Digital servo system, Flatbed | |

| Media hold-down method | Cling mat | Adhesive sheet / mat |

| Effective cutting area | 590 x 430 mm (23.2 x 16.9 inch) | 860 x 600 mm (33.8 x 23.6 inch) |

| Mountable media | 500 mm (19.6 inch) (Y-axis direction) |

666 mm (26.2 inch) (Y-axis direction) |

| Media type | Marking film (vinyl, fluorescent, and reflective) Stiff paper/card (for stencils, etc.) up to 0.5 mm thick *1 Polystyrene foam sheets up to 0.8 mm thick *2 Sandblast rubber sheets up to 1.0 mm thick *2 Microflute board (F/G grades) Clear sheets for plastic boxes High-intensity reflective film *3 |

|

| Maximum cutting speed | 750 mm/s (30 inch/s) (1 to 75 cm/s in 23 steps) | |

| Cutting pressure | Tool 1: Max. 5.88 N (600 gf), in 48 steps Tool 2: Max. 2.94 N (300 gf), in 30 steps |

Tool 1, Tool 2: Max. 5.88 N (600 gf), in 48 steps |

| Minimum character size | approx. 5 mm square (varies with the character font and media) | |

| Mechanical resolution | 0.005 mm (5μm) | |

| Programmable resolution | GP-GL mode: 0.1/0.05/0.025/0.01 mm, HP-GL™ *4 : 0.025 mm | |

| Distance accuracy | Max 0.2% of the distance moved or 0.1 mm, whichever is larger *5 | |

| Perpendicularity | Max 0.3 mm / 430 mm | Max 0.4 mm / 610 mm |

| Repeatability | Max 0.1 mm *5 | |

| Standard interfaces | RS-232C, USB2.0 (High speed) | |

| Buffer memory | 2 Mbyte | |

| Command sets | GP-GL and HP-GL™ *4 emulation (selected by menu) | |

| Number of tools | 2 tools | |

| Cutter blade, pen, and tool types |

Cutter blade: supersteel Pen: oil-based ballpoint pen Creasing/scoring tool |

|

| Others | ARMS (Advanced Registration Mark Sensing System), Reverse-side cutting and creasing with ARMS, Copy function, Creasing function, Repeatedly cut function | |

| Power supply | 100 to 240 VAC, 50/60 Hz (Auto switching) | |

| Power consumption | Max. 120 VA | |

| Operating environment | Temperature: +10 to +35 degree C (44 to 95 degree F) , Humidity: 35 to 75% RH (non-condensing) | |

| Guaranteed accuracy environment | Temperature: +16 to +32 degree C (55 to 90 degree F), Humidity: 35% to 70% RH (non-condensing) | |

| External dimensions (W x D x H) *6 |

857 x 780 x 200 mm *7 (33.7 x 30.7 x 7.9 inch) |

1172 x 962 x 200 mm *7 (46.1 x 37.9 x 7.9 inch) |

| Weight | approx. 19 kg (42 lbs.) | approx. 27 kg *10 (60 lbs.) |

| Compatible OS *8 | Windows 10 / 8.1 / 8 / 7 , Mac OS 10.7 to 10.12 | |

| Supported software *8*9 | Cutting Master 4, Graphtec Pro Studio, Graphtec Studio(for Mac) | |

| Certifications | UL , cUL , CE making, FCC-A, EN55022-A, RoHS | |

*1. The CB15U or CB15U-K30 cutter blade is used.

*2. The CB15U-K30 or CB15U-K20 cutter blade is used.

*3. The CB15UA cutter blade is used.

*4. HP-GL™ is registered trademark of the Hewlett-Packard Corporation of the United States.

*5. When operated with Graphtec specified media and conditions.

*6. Tolerance: +/- 5 mm

*7. The stand is not included.

*8. For more information about Windows and Macintosh compatibility, please check the website or contact with your local representative of Graphtec

*9. The software can be used by downloading from Graphtec website.

Standard Accessories

| item | Q'ty | Description |

|---|---|---|

| Power cable | 1 | |

| Cutting blade holder | 1 | PHP33-CB15N-HS |

| Cutter Blade | 1 | CB15U-2 (2 blades/pack) |

| Oil-based ballpoint pen | 1 | KB700-BK (Black) and PHP34-Ball (pen holder) |

| Creasing tool | 1 | CP-001, For FC4510-60 only |

| Cling mat | 1 pc each of CM-0004 and CM-0005 for FC4550-50 | |

| 2 pcs each of CM-0004 and CM-0005 for FC4510-60 | ||

| Media positioning plate | 2 | |

| USB CABLE (2.9 m) | 1 | CBL1112ACL2-2.9M |

| DVD/CD-ROM | 1 | User's manual |

| Quick Start Guide | 1 | |

| Usage Precautions | 1 |

Cutting Blade Holder

PHP33-CB09N-HS

Cutting Blade Holder

PHP33-CB15N-HS

Cutting Blade Holder

PHP35-CB09-HS

Cutting Blade Holder

PHP35-CB15-HS

Cutting Blade

CB09UA-5

Cutting Blade

CB09UB-5

Cutting Blade CB09UB-K60-5 (USA 30°, Japan 60°)

Cutting Blade

CB15U-5

Cutting Blade

CB15U-2SP, 5SP

Cutting Blade CB15U-K30

(USA 60°, Japan 30°)

Creasing Tool

CP-001

Pen

KF700-BK, KF700-RD, KF700-BL

Pen Holder

PHP34-BALL

Oil-based Ballpoint Pen

KB700-BK

| Item | Model Name | Description |

|---|---|---|

| Cutting blade holder | PHP33-CB09N-HS | Cutting blade holder for CB09UB blade |

| Cutting blade holder | PHP33-CB15N-HS | Cutting blade holder for CB15U type blades without spring |

| Cutting blade holder | PHP35-CB09-HS | Cutting blade holder, metal tip for CB09UB blade |

| Cutting blade holder | PHP35-CB15-HS | Cutting blade holder, metal tip for CB15U type blades without spring |

| Cutting blade | CB09UB | Cutting blade, 0.9 mm, 45 degree, For Vinyl media up to 0.25mm Cutting blade holder : PHP33-CB09N / PHP35-CB09 |

| Cutting blade | CB09UB-K60 | Cutting blade, 0.9 mm, 30 degree (Japan 60 degree) For Ultra thin media, Cutting blade holder : PHP33-CB09N / PHP35-CB09 |

| Cutting blade | CB15U | Cutting blade, 1.5 mm, 45 degree, For Thick media up to 0.5mm Cutting blade holder : PHP33-CB15N / PHP35-CB15 |

| Cutting blade | CB15U-2SP, 5SP | Cutting blade, 1.5 mm, 45 degree, with spring, For Thick media up to 0.5mm Cutting blade holder : PHP31-CB15B*/ PHP32-CB15* |

| Cutting blade | CB15U-K30-5 | Cutting blade, 1.5 mm, 60 degree (Japan 30 degree) For Sand-blast rubber or thicker media up to 0.5mm Cutting blade holder : PHP33-CB15N / PHP35-CB15 |

| Cutting blade | CB15U-K20-2SP | Cutting blade, 1.5 mm, 20 degree (Japan 80 degree) For Sand-blast rubber, Cutting blade holder : PHP31-CB15B*/ PHP32-CB15* |

| Cutting blade | CB15UA | Cutting blade, 1.5 mm, 45 degree, For High intensity reflective film Cutting blade holder : PHP33-CB15N / PHP35-CB15 |

| Cutting blade | CB15UA-K30 | Cutting blade, 1.5 mm, 60 degree (Japan 60 degree) For High intensity reflective film Cutting blade holder : PHP33-CB15 / PHP35-CB15 |

| Creasing tool | CP-001 | Stick type, for cardboard |

| Pen | KF700-BK | Water-based fiber-tip pen (Black) |

| KF700-RD | Water-based fiber-tip pen (Red) | |

| KF700-BL | Water-based fiber-tip pen (Blue) | |

| Pen holder | PHP31-FIBER | Pen holder for KF700 series pen |

| Oil-based ballpoint pen | KB700-BK | Pen (black) |

| Pen holder | PHP34-BALL | Pen holder for KB700 Pen. |

| Adhesive mat | CM-0002 | Size 435 x 610 mm, 1 mm thick, for creasing |

| Adhesive sheet | CM-0003-R1A | Double-side coated roll, size 545 mm x 20 m |

| Cling mat | CM-0004 | Low tack cling mat, size 435 x 610 mm |

| Cling mat | CM-0005 | Micro suction cling mat, size 435 x 610 mm |

Looking for quality vinyl cutter machine for commercial, intermedia or entry level, Graphtec can help your vinyl cutting process become easier and improve productivity. Graphtec globally manufactures hight quality vinyl cutter machines. With years of experience in plot cutter, Graphtec is industry leader in desktop vinyl cutter, desktop vinyl cutter machine, sticker cutter, sticker cutter machine, sticker cutting machine. Graphtec is trusted by world renowned organizations around the world, our cut plotter precisely cut vinyl sheet and cut vinyl roll. If you are looking for the high quality vinyl roll feed cutters, Graphtec specialists are onsite to provide you guidelines on how to choose roll feed cutter machine or flatbed cutter machine to suit your production needs, we have you covered!