AEROSPACE AND DEFENSE

From stable production cycles to mechanical and electrical systems testing, component manufacturers to aerospace and defense industry are continuously challenged to set up test conditions to meet the ever-increasing demand for extended product life cycles. Graphtec dataloggers and data platform offers accurate measurement backed by 65 plus years of experience in developing recorders for physical signal measurements. Unlike traditional test systems where revamps and changes in the test conditions can force expensive and lengthy proposals, Graphtec dataloggers offer versatile test set up where you can record multiple channels beyond a thousand channels with no need for programming or retrofits.

Module expansion and additional channel blocks are all that is necessary based on the need of your channel requirement and speed. Graphtec’s portable feature will offer flexible design that takes you from one test to another quickly and accurately as you develop new test scenarios for future demands.

ADVANTAGE OF THE GRAPHTEC DATA LOGGERS / DATA PLATFORM

CHANNEL ISOLATION

Measurement accuracy is achieved by offering high channel isolation and proper grounding techniques. Graphtec offers industry leading channel isolation at multiple channels.

STANDALONE

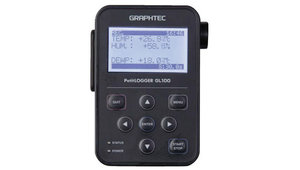

Portable configuration of Graphtec Dataloggers provides data acquisition at the palm of your hand. Set up your conditions, save, and move on to one test to another with relative ease.

LOW-COST

Forget about spending weeks and months for setting up Automated Test System (ATE) to configure the next scenario. Build your test criteria within hours

TEST CATEGORIES

Environmental Testing

Flight Test Recorder

Component Level Testing

Fatigue Testing

Motor Development Tests

Material Testing

Data Acquisition

Vibration and multi-signal Inputs

Production Life Cycle Stress Tests

Portable Structural Testing

Weapons Testing

Discontinuity Testing

CHOOSE TOP PRODUCTS

Power Monitoring Test for Satellite Development

Dynamic monitoring of power/voltage/current signals for solar powered satellite development.

Environmental Testing for Aerospace Component

Optional Display capability of the GL7000 allows dynamic recording of fast sampling intervals for temp and line voltage signal inputs from various sensors while recording directly onto Excel spreadsheet.

Simulate Anomalies on on-site Robotics Equipment

Record the output from automated robotics equipment and output the signal to simulated testers. Monitor and look at the variances in movement using the output module from GL7000.

Monitor both Control Signals and Physical Vibration Measurement for secondary analysis.

Record the output from automated robotics equipment and output the signal to simulated testers. Monitor and look at the variances in movement using the output module from GL7000.

Monitor both Control Signals and Physical Vibration Measurement for secondary analysis.

Records the operating conditions of the controllers for the vibration shakers as well as the actual physical measurement on the shaker table so you have an accurate data on the sensitivity of the test component.

Performance Testing for Gaskets

Measure gasket strain, applied pressure, and temperature to test gasket capability.

Discontinuity Testing for Battery Supply under Low Current Scenario

Testing for battery loads to make sure low current scenario still charges the battery cells.

Continuous Recording of Dynamic Power and Current signal from Robotics Welding Machine

Dynamic recording of current levels and temperature levels can compare the consistency of how the welding machines are performing while the robotics are operating.

Measuring Load Signal from Tension Testers

Strain measurement from weight scales on load cells from a tension testers can be recorded at high sampling intervals with a trigger start to record critical dynamic information.

Monitoring Fast Changing Signal from Flaw Detectors

Dynamic monitoring is required when using ultrasonic flaw detection systems. Analog outputs from the flaw detectors can be recorded onto the GL980 for extended period. (2 days 6 hours at 1ms interval. 40sec at 100kS/s)

RPM Measurement of Belt Conveyers on a Production Line

F/V converter or tachometers can be used to measure the RPM speed of the motor and the belt conveyer speed.

Maintenance Measurement for Industrial Gas Turbines

Maintenances for Emergency back up generators and co-generation system can be done using the GL980 monitoring 500V high voltage range in the generator and the relative temperature ranges on the boilers.

Maintenance Measurement for Aerospace Component Production Line

Multi-input usage of the GL980 allows measurements of both voltage and temperature to gauge the relative variables that affects the production line output. GL980 samples recording at dynamic speed to breakdown the performances in detail.

ECU Temperature Profile

Measure the temperature profile data of the ECU blocks with environmental test chamber and use it as a reference data for mass production. Perform dynamic signal recording (for electrical signal) on top of the slow running temperature data.

Measurement of Control Equipment

Measure the control signal of the control devices including voltage and temperature to troubleshoot problems and monitor its conditions.

Measure Variables as X-Y Recorder

Variance the relationship between displacement and strain amount converted from the compression test device into voltage signals displayed in XY graph.

Environmental Monitoring of Semiconductor Manufacturing Equipment

Manage the environment with multi-channel measurement to produce high quality products.

Measurement of Piping Temperature in Manufacturing Plants

Measure multiple temperature points inside the piping structure of manufacturing equipment at multiple points.

Monitoring of High Precision Equipment for Thin Film Production and Impact Sealers

Measure the control signal and the power drive voltages with manufacturing equipment such as production surface-treated film materials, and monitor the condition of the equipment.

Testing of Self-propelled Vacuum Cleaners

Precisely measure the internal temperature along with the control signal of small household appliances.

Continuous Measurement of Static Electricity

Check electrostatic change after passing through an ionizer with up to 10 channels using static electricity sensor.

Temperature Mapping for Drying Furnace and Environmental Chambers

Measure the temperature profile at drying points of the test components inside dry furnaces at multiple points up to 10 channels.

Recording Flow Rates from 4-20mA Signals

Measure pipe flow rates/pressure signals from pressure and flow transducers with 0-10V output or 4-20mA current loop signals used with the 250ohm shunt resistor and scale your input to display and log original unit of measurement in PSI or in cubic inches per second and other custom units.

Monitor the Output from Displacement Sensors

Check the output from the displacement sensors with multiple channels up to 10 channels.

Production Line Testing

Collect production situation data for daily purposes via SD card and LAN interface using the GL240.

Monitor Output from Automated Test Equipment

Monitor time-based variables from various instrumentation and automated test equipment with a quick portable 10 channel datalogger to troubleshoot and check equipment.

Measurement Temperature and Humidity on Production Lines

Monitor the temperature and humidity levels on products along with the productio line using the GL100 compact datalogger.

Electrical Power Monitoring of Components in Production Line

Easily install GL100s to the production line as well as to the components to collect vital power data using wireless LAN.