CUTTING MASTER 4 TIPS AND VIDEO TRAINING

Cutting Master 4 plug-in software for Adobe Illustrator and CorelDRAW Graphics Suite can send the cutting object to the plotter and can also be used to control the plotter. It has a variety of features as the preview window, the cutting condition settings and others.

Cutting Master 4 enables you to take a full advantage of the plotter with easy operation.

3 EASY STEPS

1 ) CREATING DESIGN

Design is created using Adobe Illustrator or CorelDRAW.

2) CUTTING MASTER 4

It checks the cutting object, adjust the position and se the cutting conditions.

3) CUT

Cutting data is transferred to the cutting plotter. The cutting plotter starts the job.

SOFTWARE FEATURES

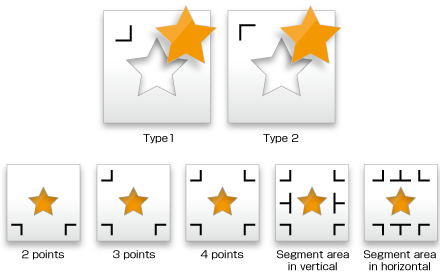

CREATING THE REGISTRATION MARKS

Registration marks can be added to the art board of the design application software. It can be selected from 10 patterns according to the design object size and the precision of axis alignment in the Print & Cut applications.

TILLING (SPLIT THE OBJECT)

The cutting object can be split into smaller tiles. When the object needs to be placed to the surface made by multiple panels or is larger than the width of the media, the object can be split to size for fit it.

MATRIX COPY

Used for creating multiple copies of the same object. The object is copied in specified matrix condition.

WEED LINES AND BORDER

The border line and weeding lines can be added around the cutting object automatically and then it is cut. It makes easier to remove the excess material from the media.

TOOL ASSIGNMENT

The Cutting Master 4 is able to assign the tool condition to the each color or the layer. The settings of tool condition as force, speed, quality (acceleration) and others can be set for the each color or the layer. It can be performed in a single job by process of different types.

SUPPORTS ARMS 6.0 ON FCX2000

Supports ARMS (Advanced Registration Mark Sensing system) 6.0. New functions such as supporting crop mark, supporting processing on the reverse side, reversed color mark are available. It enables to enhance usability.

OFFLINE OPERATION USING USB FLASH MEMORY

Plot data is created from the design by using Cutting Master 4, then it is saved to USB memory. The plot data file can be selected from the USB on the plotter, then cutting is performed. This simplified work-flow enables users to operate without a computer.

[Compatible models] FCX2000

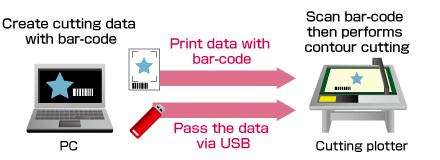

DATA MANAGEMENT USING BAR-CODE WITH USB FLASH MEMORY

In Print & cut operation, the plot data is automatically selected from USB flash memory by scanning the bar-code printed on the media. Bar-code is created by using Cutting Master 4. This prevents the usage of incorrect data, and improves work efficiency.

[Compatible models] FCX2000

COPYING DATA WITH REGISTRATION MARKS

After data is sent the first time, it can be copied multiple times without a PC. In the FCX2000, the first four marks are scanned on the first sheet, and only the first mark in subsequent sheets. Cutting Master 4 is able to configure FCX 2000 to execute copy in this condition. This improves productivity by shorting scan detection time.

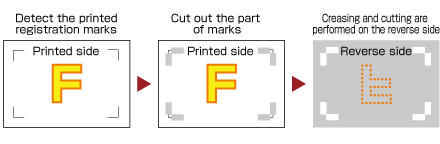

REVERSE SIDE CUTTING / CREASING USING REGISTRATION MARKS

Cutting and creasing can be aligned to the printed graphics even if processing is performed on the reverse side of the media. This prevents any scratches or damage to the printed graphic. Cutting Master 4 is able to configure FCX2000 to execute the process in this condition.

[Compatible models] FCX2000

EXPANDED CUTTING AREA

It expands the cutting area to include objects outside of the area enclosed by registration marks. Production efficiency is enhanced by reducing media waste.

[Compatible models] CE6000 PLUS / FCX2000 / FC8600

SUPPORTED BY STANDARD CROP MARKS

Cutting is aligned to the printed graphic by printing the industry standard crop marks. Adding special marks with Graphtec software is not necessary. Cutting Master 4 is able to get information of crop mark from Adobe Illustrator and send it to FCX2000.

[Compatible models] FCX2000

CREATING REGISTRATION MARKS IN REVERSED COLOR

Cutting Master 4 is able to create the registration marks in either one of the normal style or reversal style. The reversal style mark has the reversed color and it is able to detect the mark on the media such as the type of glossy or shiny. It enables to expand the compatible media for the Print & Cut applications.

REGISTRATION MARK FUNCTION AND OTHERS

■ Number of marks: 2 / 3 / 4 points

■ Multiple-mark compensation

■ Segment area compensation

■ Expanded effective cutting area

■ First mark compensation

■ Support process in the revers side

■ Reversed color

■ Crop mark of Adobe Illustrator

■ Save plot data into USB flash memory

■ Create bar-code and save it with plot data

CONTROL PLOTTER

■ Matrix copy (vertical and horizontal direction)

■ Multiple pass

■ Set cutting conditions (five items)

■ Assign cutting conditions by color or layer

■ Import or export cutting conditions

■ Support connection of multiple cutter