FAQ - VIDEO > PRINT & CUT ISSUES > OFFSET ISSUES

OFFSET ISSUES

When the cut line does not line up properly, it can be a simple fix depending on how the misalignment looks like.

If all the cut lines are moved to one side either left, right, away, or closer to you while standing in front of the cutter that will be a simple calibration.

If the cut line offset is going in different directions, the cause may be outside of the cutter. Follow these 3-recommendations:

#1 Recommendation

The registration mark method (4 marks or Segmented Marks) can affect the cutting accuracy. 4-marks should be used on short job, less than 40" in length, for a job greater than 40" in length, segmented marks should be used. A set of segmented marks every 20" is recommended.

#2 Recommendation

If the offset is uniform check and adjust the cutter calibration

Click >> Learn how to adjust sensor offset via the cutter control panel

#3 Recommendation

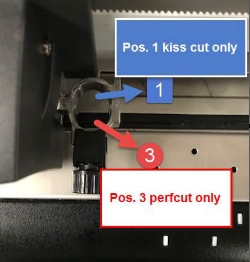

In FC8000/8600 models, the cutline is off about 1/4 inch in the X-direction, please check the position of blade-holder on the cutting head. Make sure it is in position 1 for kiss cutting.

IMPORTANT: If using 3rd party software like Onyx or Flexi, Caldera. If on Ethernet-connection, please connect via USB (just for test purposes), make necessary changes on the port setting of the software and try again.

If you still have an issue, please try a job directly from Adobe Illustrator/CorelDRAW using Cutting Master Plug-in, or Graphtec Pro Studio/Graphtec Studio.

If successful cutting from the suggested Graphtec software, please contact your 3rd party software for support.

If un successful or same results cutting from the suggested Graphtec software please contact Graphtec Technical Support

< BACK